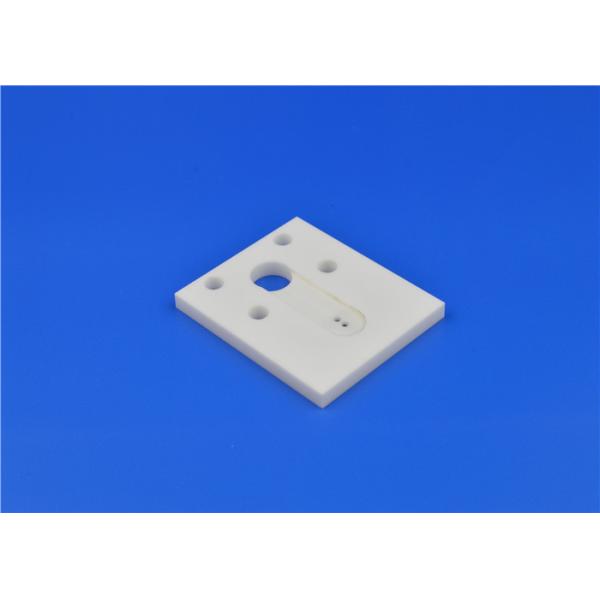

Advanced Ceramics Machinable Zirconia Ceramic Guide Block for Solar

Photovoltaic Systems

Ceramic guides have been used in various applications within the

saw mill industry for the past 15 years. Our Delta 14 inch, Delta 12 & 16 inch, Import, and Craftsman Old Style

Ceramic Guideblock products all are suitable for use with any blade

width.

Made of virtually indestructible ceramic, the ultra-smooth surface,

low friction thrust bearings and guide block products provide

excellent support to bandsaw blades. They run cooler, provide truer

tracking, and make the blades run much smoother and quieter.

Why You Need Mingrui Ceramic Guideblocks

Our guide blocks reduce friction and can reduce pitch build-up on

the blade. They work with blades 1/4″ wide and up. Keep the blocks

clear of the blade teeth. Our import set will fit Jet and General

14″ saws, and most Delta 14″ clones. All block sets come as a set

of 4 that includes both upper and lower guides.

The specification of the alumina ceramic plates

1. Material : 96% alumina, 99% alumina, 99.5% alumina, zirconia,

silicon nitride, silicon carbide optional

2. Dimensional capability Side length max. 500mm x 600mm, Thickness

can be range from 0.15mm to 30mm

3. Surface treatment: natural surface, lapping, diamond-like

polishing, metallization, glazed

4. We have many selections of al2o3 ceramic plates, refer to the

checklist of standard size in different purity.

| S/N | Material | Length

(mm) | Width

(mm) | Thickness

(mm) | S/N | Material | Length

(mm) | Width

(mm) | Thickness

(mm) |

| 1 | 96%

alumina | 114 | 114 | 0.385 | 25 | 99%

alumina | 49 | 42 | 3 |

| 2 | 190 | 138 | 0.5 | 26 | 100 | 25 | 3 |

| 3 | 280 | 240 | 0.6 | 27 | 105 | 95 | 5 |

| 4 | 190 | 138 | 0.75 | 28 | 140 | 140 | 5 |

| 5 | 142 | 132 | 0.8 | 29 | 192 | 40 | 6 |

| 6 | 130 | 109 | 1 | 30 | 150 | 140 | 8 |

| 7 | 114 | 114 | 1 | 31 | 300 | 180 | 8 |

| 8 | 230 | 190 | 1 | 32 | 165 | 165 | 8 |

| 9 | 280 | 240 | 1 | 33 | 100 | 100 | 10 |

| 10 | 395 | 83 | 1 | 34 | 280 | 240 | 10 |

| 11 | 92 | 19 | 1.9 | 35 | 105 | 50 | 12 |

| 12 | 51 | 4 | 2 | 36 | 300 | 200 | 10 |

| 13 | 45 | 14 | 2.5 | 37 | 280 | 240 | 15 |

| 14 | 160 | 120 | 3 | 38 | 300 | 200 | 15 |

| 15 | 160 | 120 | 4 | 39 | 530 | 250 | 15 |

| 16 | 160 | 120 | 5 | 40 | 300 | 200 | 20 |

| 17 | 99%

alumina | 10 | 25 | 2 | 41 | 400 | 400 | 25 |

| 18 | 10 | 30 | 2 | 42 | 99.5% alumina | 150 | 126 | 2 |

| 19 | 24.8 | 24.8 | 2.5 | 43 | 156 | 150 | 2 |

| 20 | 24 | 24 | 3 | 44 | 180 | 150 | 2 |

| 21 | 30 | 20 | 3 | 45 | 150 | 70 | 4 |

| 22 | 30 | 25 | 3 | 46 | 150 | 150 | 4 |

| 23 | 36 | 30 | 3 | 47 | 156 | 150 | 4 |

| 24 | 36 | 36 | 3 | 48 | 180 | 150 | 4 |

Remark:

All the above big size ceramic sheets can be cut to specific

dimensions per customers' requirement.

Application

Properties of Alumina and Zirconia Ceramic :

| Properties | Units | 95 Alumina | 99 Alumina | ZrO2 |

| Density | g / cm³ | 3.65 | 3.92 | 5.95-6.0g/cm³ |

| Water absorption | % | 0 | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 | 10.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 | 210 |

| Poisson's ratio | / | 0.21 | 0.22 | 0.3 |

| HV Hardness HV | MPa | 1400 | 1650 | 1300-1365 |

| Flexural Strength @ room temperature | MPa | 280 | 310 | 950 |

| Flexural Strength @700°C | MPa | 220 | 230 | 210 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 | 2000 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 | 10 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 | 2-2.2 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 | >1015 |

| Max use temperature | °C | 1500 | 1750 | 1050 |

| Resistance to acid alkaline | / | high | high | high |

| Dielectric Constant | / | 9.5 | 9.8 | 26 |

| Dielectric Strength | KV/mm | 16 | 22 | / |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 | 280-350 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 | 252 |

Company Introduction:

We ( Dongguan Mingrui Ceramic Technology Co., Ltd ) are a

professional manufacturer specialized

in R&D, manufacturing and selling customized all kinds of high

precision zirconia and alumina ceramic parts . Our main products

include ceramic rod , ceramic tube, ceramic plunger, ceramic valve,

ceramic plate, ceramic shaft and bearing , ceramic nozzle etc ,

which are mainly used in industrial fields of Machinery,

Petrochemical oil and gas, Valves, Automotive, Food Processing,

Fluid Handling, Process Control, Thermal Processing, Aerospace,

Defense, Eletronic and Electrical, Textile, Mechanical,

Engineering, Mineral Processing, etc.

We have a full service include mold design and development ,

ceramic forming , precision machining

and precision detection technology. We have achieved great

successes in particular requirements

which is based on cooperating with Tsinghua University and getting

rich experience by our professional technical engineer teams . Our

factory have an unique technical called mirror polishing which

improve

our products more smooth , bright than other competitors.

FAQ :

1. Are you a manufacturer ?

Yes we are a ceramic manufacturer . We proceed with the whole

process start from Powder material to forming , sintering ,

machining, marking , inspection , packing , we do the whole process

.

2. What kind of industry ceramics do you have ?

We specialized in 95% 97% 99% alumina ceramic and zirconia ceramic

parts .

3. What kind of molding method do can you supply ?

Dry Pressing , isostatic pressing , grouting , hot-chamber die

casting , tape casting , injection molding, etc, injection molding

and isostatic molding is the most commonly used.

4.What stabilizer do you use when processing ?

Yttria stabilizer is the most commonly used in our industrial

ceramic parts.

5.Can you produce free samples for me ?

Yes usually , we can produce free samples for you but it is up to

the product complexity .

6.What terms can you accept for payment ?

T/T, L/C , Western union , Money Gram and Paypal is welcome , but

paypal and western union only for small -sum payment.